Solidification behaviour of single crystalline nickel based superalloys

Characterization

Ni-based superalloys are widely used to fabricate turbine blades of aero-engines and stationary gas turbines. In the nickel-based superalloys, grains with <001> orientation aligned parallel to the temperature gradient have the fastest growth rate and overgrow the slower growing orientations. The morphology of solid-liquid interface in directionally solidified superalloys can be related to the G/V ratio, where G is the temperature gradient in the melt ahead of the solidifying front and V is the solidification rate. Depending on solidification parameters, nickel based single crystalline superalloys can grow on planar, cellular or dendritic interface.Objectives

- To prepare single crystalline nickel based CMSX-4 superalloy with defined microstructure using directional solidification in Bridgman type apparatus.

- To study solidification behavior of CMSX-4 superalloy at steady-state conditions.

- To study columnar to equiaxed transition (CET) of CMSX-4 at non-steady conditions using power down technique and constant cooling rates.

Achievements

- Single crystalline CMSX-4 ingots with dendrites well-oriented in the [001] crystallographic direction were prepared in Bridgman type apparatus.Nearly square sections of the γ’precipitates on (001) crystallographic plane as well as similar nearly square sections on (010) and (100) crystallographic planes confirmed their cuboidal morphology before ageing.

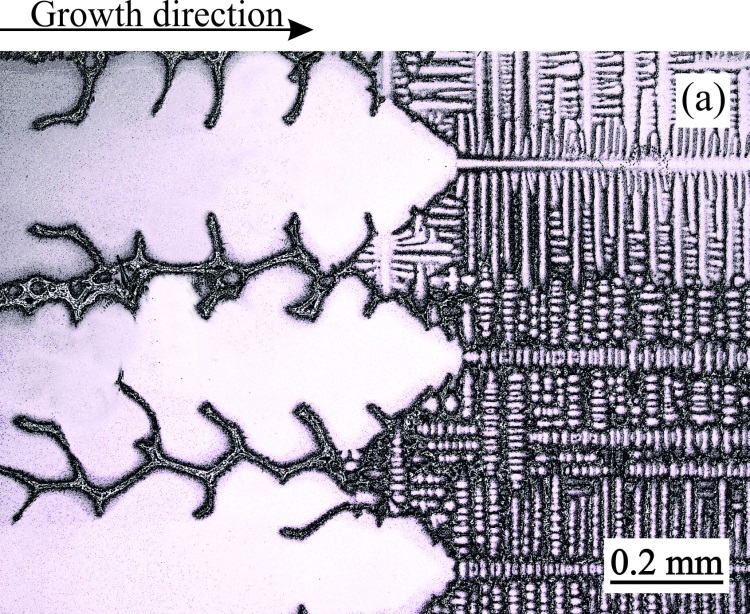

- The single crystal growth of CMSX-4 superalloy at steady-state conditions leads to the growth at a planar interface at low solidification rate of 1mm/h and to dendritic one at higher solidification rates.

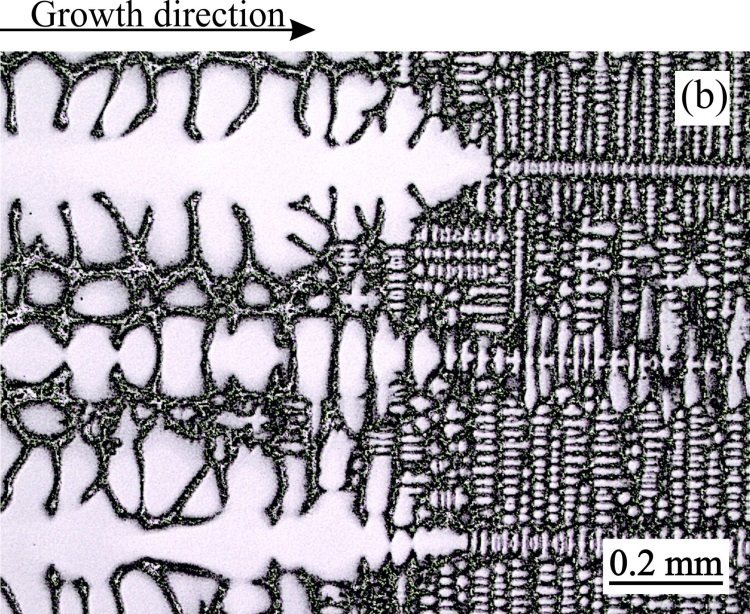

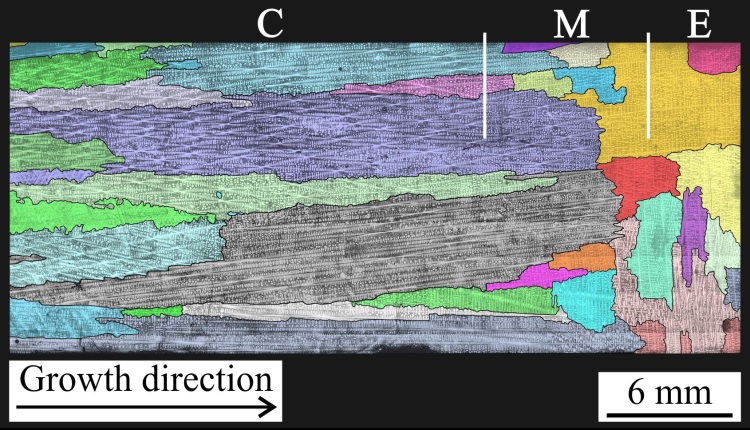

- During non-steady state solidification at constant cooling rates using power down technique, the growth of columnar grains is stopped by the equiaxed grains, which nucleate in the liquid ahead of growing columnar grain front. The position of CET depends on the cooling rate and decreases towards the beginning of the columnar grain region with increasing cooling rate.

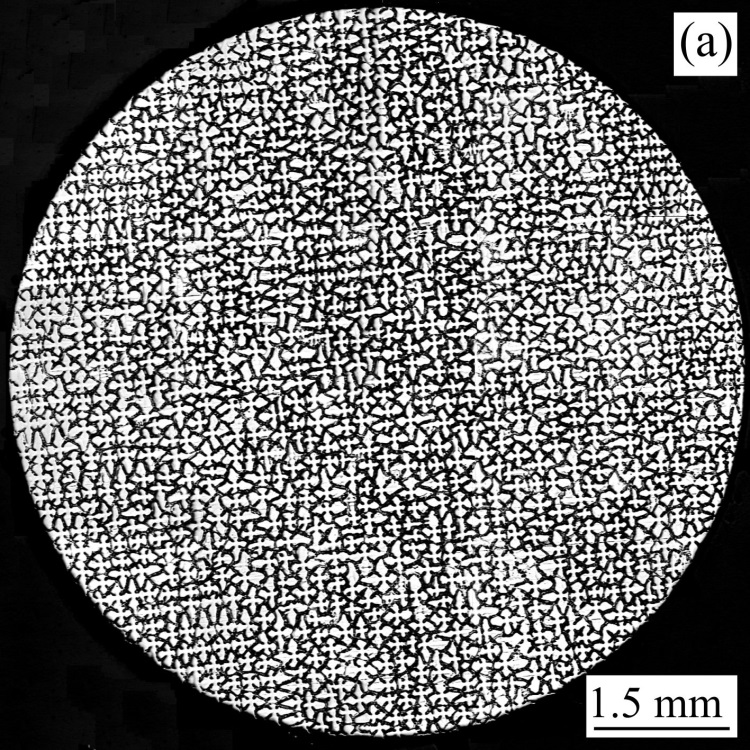

OM micrograph showing the typical distribution of dendrites in single crystalline sample on transverse section

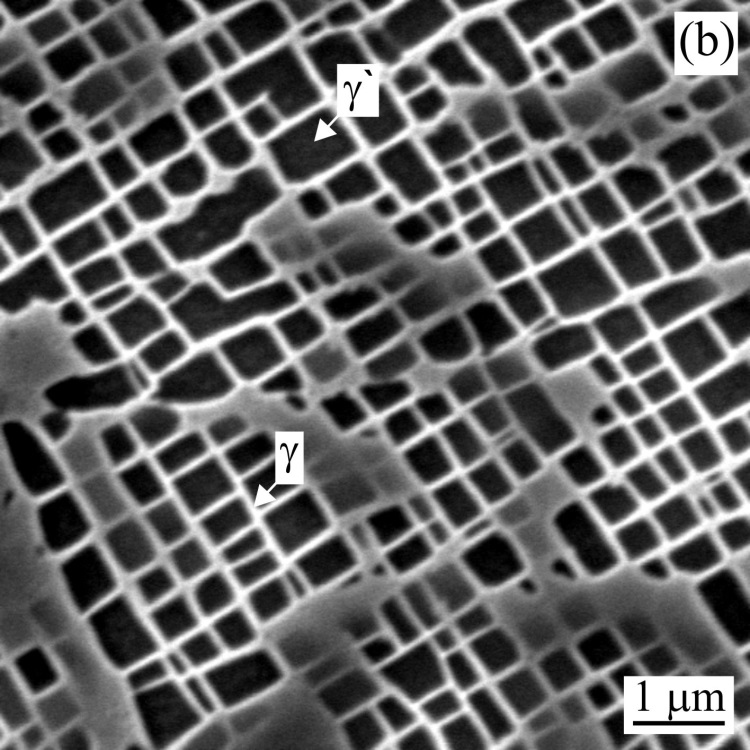

OM micrograph showing the typical distribution of dendrites in single crystalline sample on transverse section SEM microstructure shows ordered γ’ (Ni3(Al,Ti)) precipitates coherently embedded in γ (Ni base solid solution) matrix with face centered cubic crystal structure

SEM microstructure shows ordered γ’ (Ni3(Al,Ti)) precipitates coherently embedded in γ (Ni base solid solution) matrix with face centered cubic crystal structure

Columnar to equiaxed transition in CMSX-4 superalloy prepared at unsteady state growth conditions

Columnar to equiaxed transition in CMSX-4 superalloy prepared at unsteady state growth conditionsAdditional reading

LAPIN, J. - PELACHOVÁ, T. - ADAMČÍKOVÁ, A. - ZEYTIN, H.K. Solidification behavior of Ni-based CMSX-4 superalloy studied by directional solidification. In 5th International Conference “Mechanical Technologies and Structural Materials”, MTSM2015, 2015, Croatian society for mechanical technologies, c/o FESB, Ruđera Boškovića 32, 21000 Split, Croatia, ISSN 1847/7917, pp. 93-100. ISSN 1847-7917.LAPIN, J. - GEBURA, M. - PELACHOVÁ, T. - NAZMY, M. Coarsening kinetics of cuboidal γ’ precipitates in single crystal nickel base superalloy CMSX-4. In KOVOVE MATER, 2008, vol.46, pp. 313-322. (Current Contents, Scopus, WOS). ISSN 0023-432X.

GEBURA, M. - LAPIN, J. Morphological changes of γ’ in Ni-based superalloy during long-term ageing. In 17th International Conference on Metallurgy and Materials, METAL 2008, [online], 2008, Červený zámek, Hradec nad Moravicí, Tanger Ltd, pp. 311-317. ISBN:978-80-87294-10-9.

Related projects

- Competence center for new materials, advanced technologies and energetics, 2011 - 2015

- Evolution and degradation of microstructure of nickel based alloys during directional solidification, heat treatments and creep, 2007 - 2009

- Evolution and degradation of microstructure of CMSX4 superalloy during ageing and creep exposure, 2005 - 2008