Advanced materials / High-temperature materials /

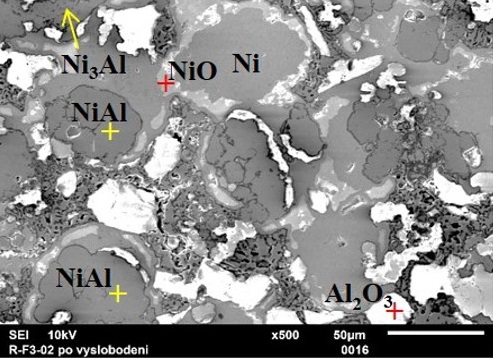

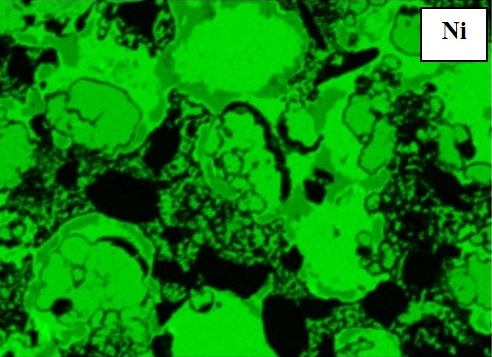

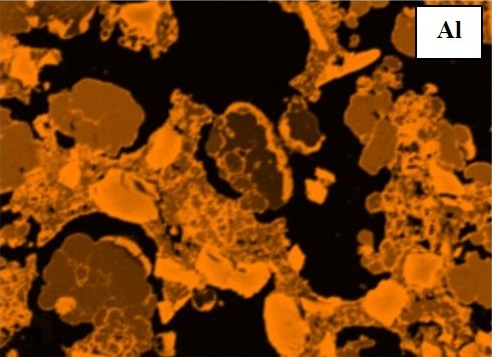

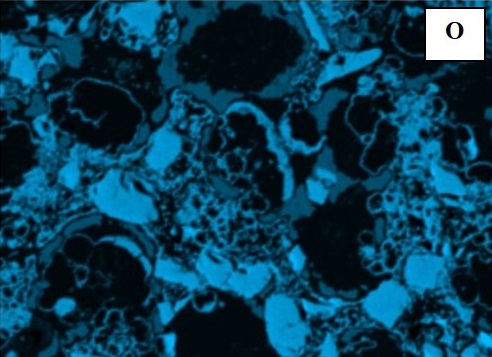

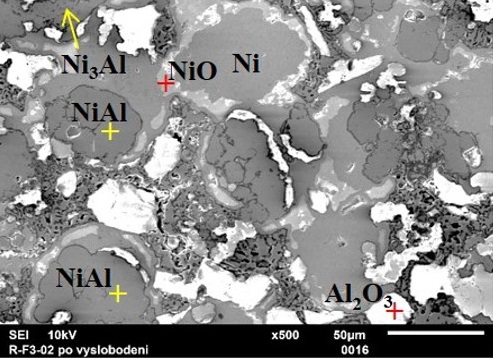

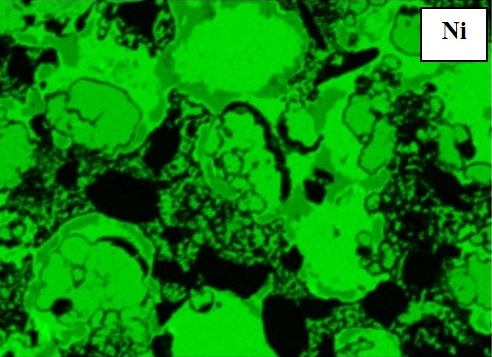

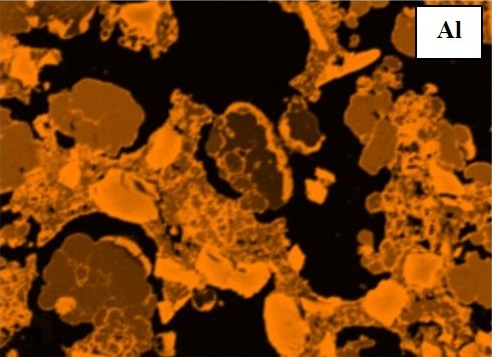

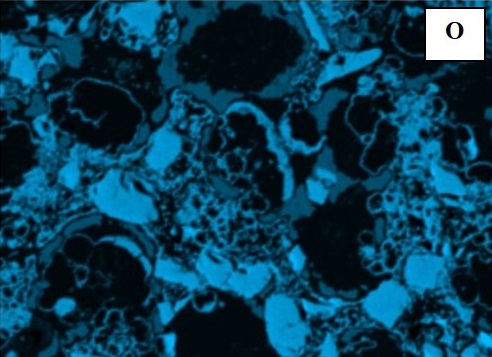

Structure of composite prepared by infiltration of oxidized preform by molten aluminium at 750 ºC and oxidized in air at 800 ºC for 1000 h. Preform was prepared by pressing of mixture of Ni and Al2O3 powders into tablet and oxidation in the air up to 800 ºC.

Structure of composite prepared by infiltration of oxidized preform by molten aluminium at 750 ºC and oxidized in air at 800 ºC for 1000 h. Preform was prepared by pressing of mixture of Ni and Al2O3 powders into tablet and oxidation in the air up to 800 ºC.

Now the thermal and mechanical properties of composites are measured.

NiAl matrix composites

General description

Nickel aluminides are attractive materials in various applications. Although, the conventional fabrication of intermetallic alloys with high melting point, consisting of NiAl and Ni3Al is technologically quite demanding process, the gas assisted reaction synthesis is the powerful tool how to fabricate high-melting Ni aluminides even at low temperatures (750 - 800 ºC).Main benefits

Nickel aluminide composites provide unique mechanical and thermal properties even in temperature range where classic Ni-Al intermetallic are extremely brittle.Main structural properties

Now the thermal and mechanical properties of composites are measured.