Services / Physical properties measurement / Basic methods /

Differential thermal analysis (DTA) is a very popular thermal analysis technique to measure endothermic and exothermic transitions as a function of temperature. The instrument is used to characterize pharmaceuticals, food/biologicals, organic chemicals and inorganics. Transitions measured include glass transitions, crystallization, melting and sublimation.

Thermogravimetry (TGA) is a technique in which the mass of the sample is monitored (balance) against time or temperature (thermal) while the temperature of the sample, in a specified atmosphere, is programmed. This technique serves the determination of material compositions. It is a common analysis method in the chemical and pharmaceutical industry.

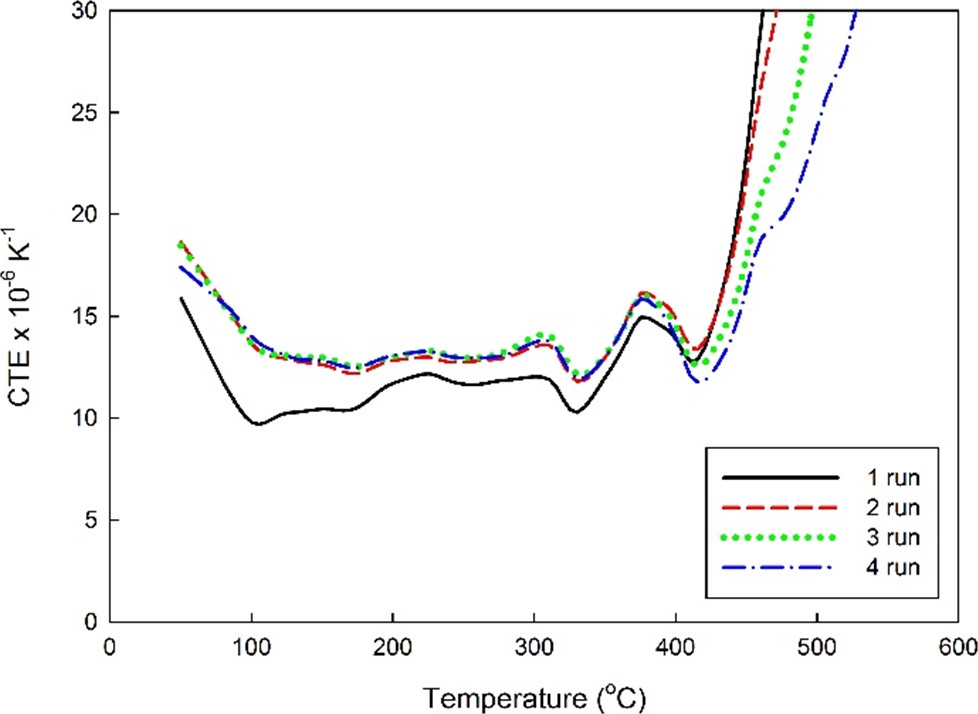

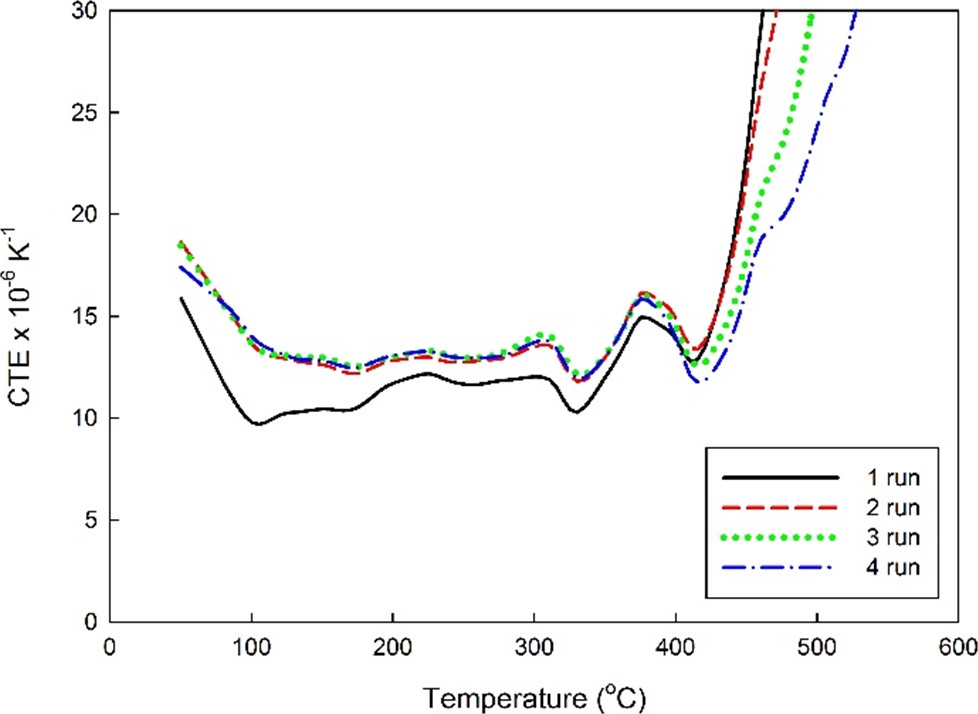

Coefficient of thermal expansion

Coefficient of thermal expansion

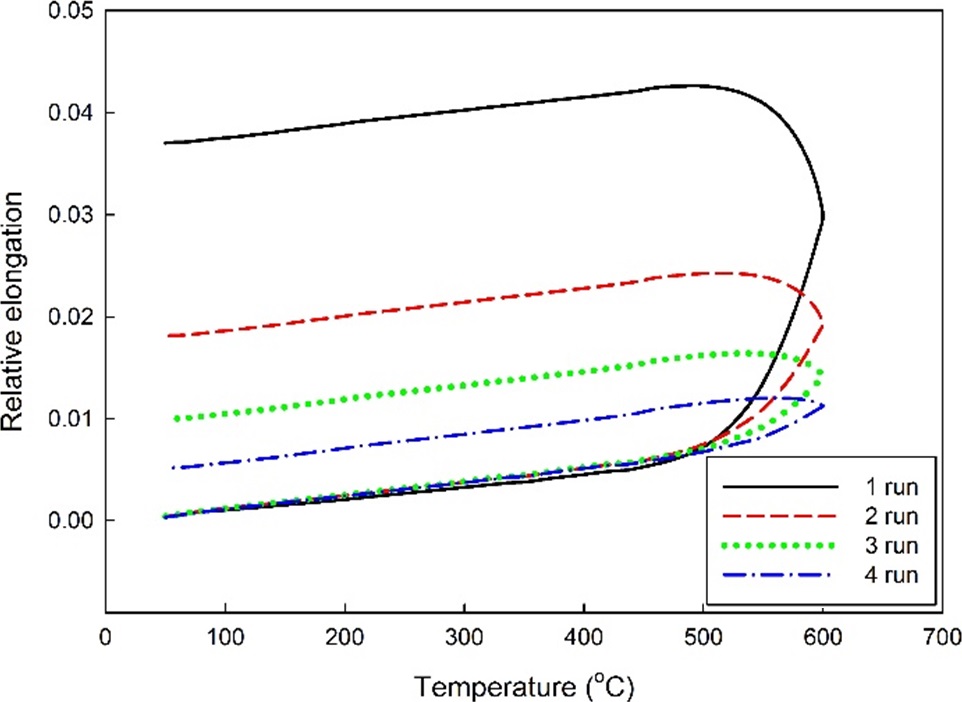

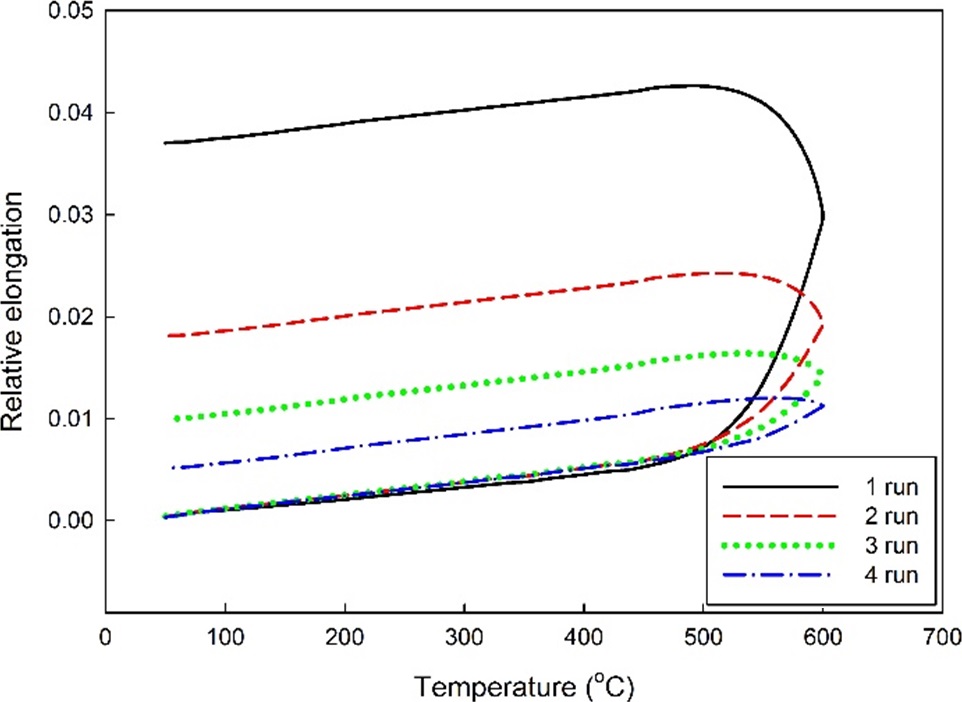

Relative elongation

Relative elongation

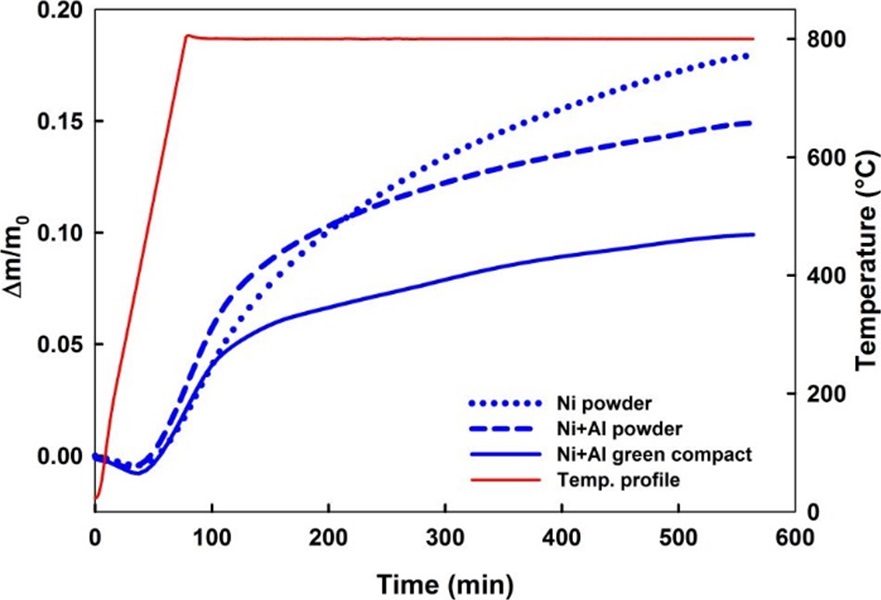

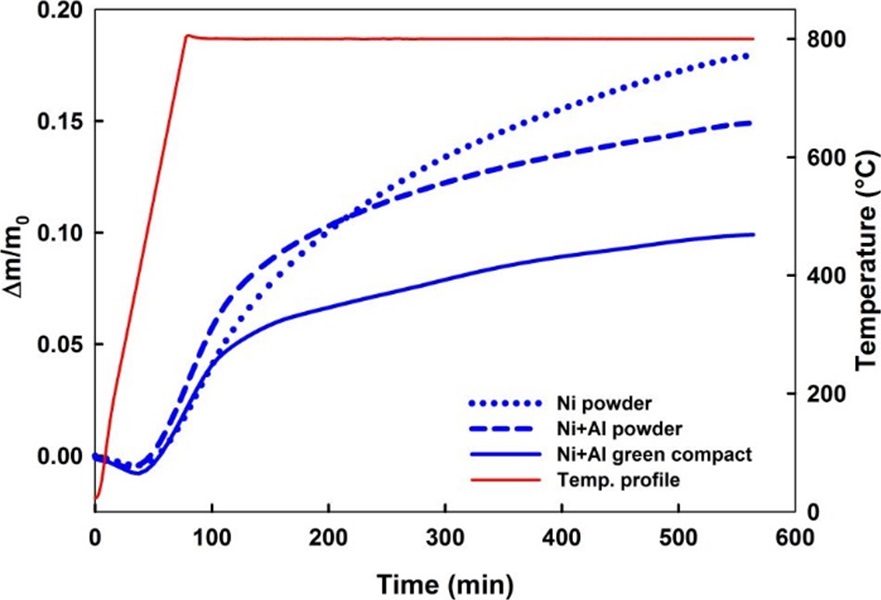

Thermogravimetric (TG) curves recorded for the Ni powder, Ni+Al powder a Ni+Al green compact oxidized at 800 °C

Thermogravimetric (TG) curves recorded for the Ni powder, Ni+Al powder a Ni+Al green compact oxidized at 800 °C

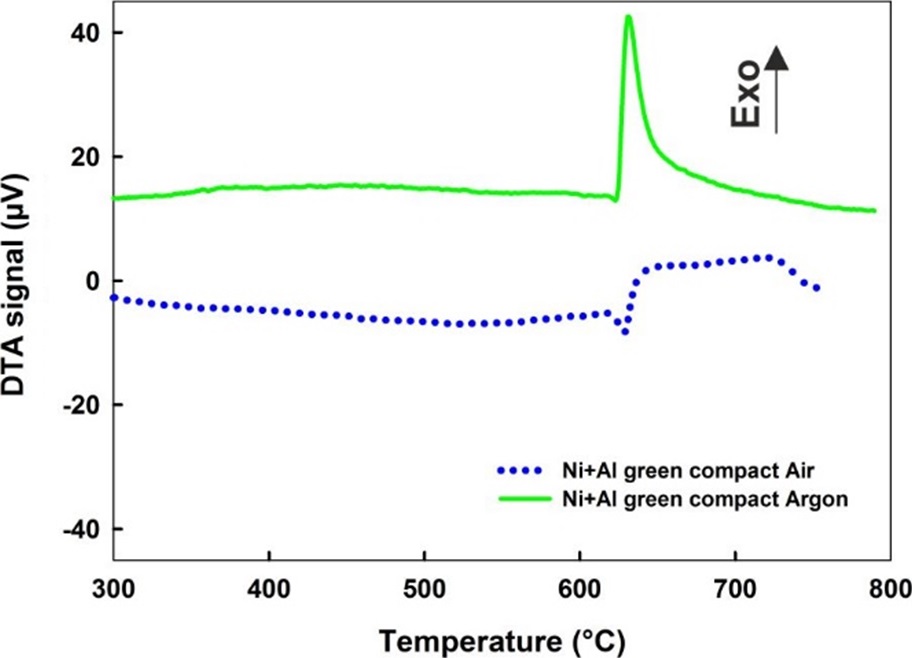

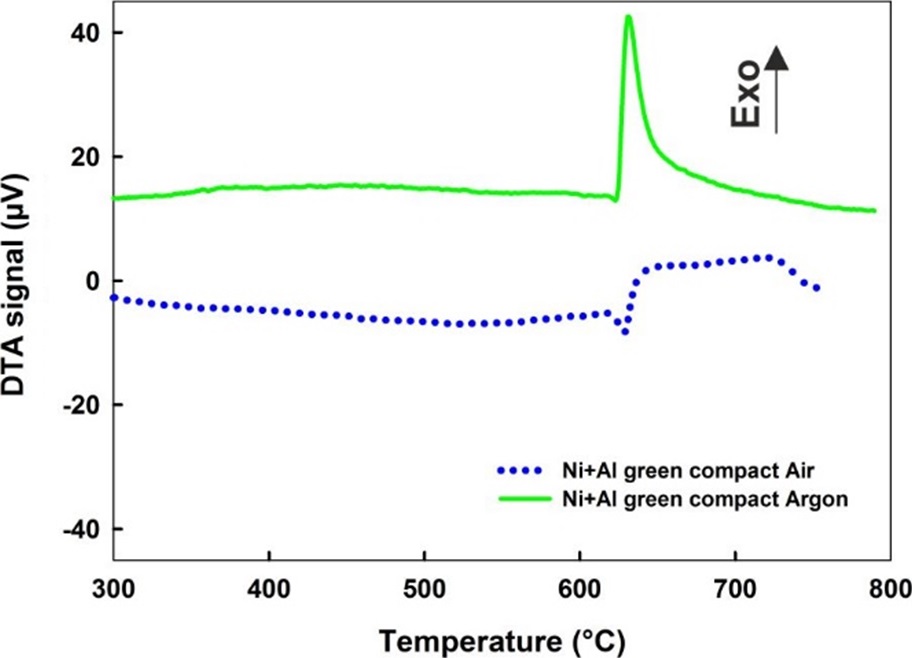

DTA record for the Ni+Al green compact heated to 750 °C in argon or air atmosphere

DTA record for the Ni+Al green compact heated to 750 °C in argon or air atmosphere

Thermal analysis

General purpose

Thermal analysis is widely used to determine thermodynamic properties, which are essential for understanding the behavior of material under different heating and cooling rates, under inert, reduction or oxidation atmosphere or under different gas pressures. Thermal analysis covers a range of techniques that allow studying various chemical processes in a solid sample such as decomposition, pyrolysis, ignition, phase transitions etc. in a highly automated way. Thermogravimetric analysis (TGA) is commonly used to measure mass loss/gain, and differential thermal analysis (DTA) and differential scanning calorimetry (DSC) are suited to study the energy changes (heat flow) in the sample caused by thermal chemical reactions. Common applications of TGA are material characterization by analysis of decomposition patters and studies of degradation mechanism and reaction kinetics. While, DTA and DSC are appropriate for determination of the temperature of phase transitions like melting point, solidification onset, recrystallization onset, evaporation temperature etc.Application of the technique

Dilatometry (DIL) is a technique in which a dimension of a substance under negligible load is measured (e.g. expansion or shrinkage measurement) as a function of temperature while the substance is subjected to a controlled temperature program in a specified atmosphere.Differential thermal analysis (DTA) is a very popular thermal analysis technique to measure endothermic and exothermic transitions as a function of temperature. The instrument is used to characterize pharmaceuticals, food/biologicals, organic chemicals and inorganics. Transitions measured include glass transitions, crystallization, melting and sublimation.

Thermogravimetry (TGA) is a technique in which the mass of the sample is monitored (balance) against time or temperature (thermal) while the temperature of the sample, in a specified atmosphere, is programmed. This technique serves the determination of material compositions. It is a common analysis method in the chemical and pharmaceutical industry.

Typical case studies

Thermocycling of the composite sample Ni/Al reinforced with alumina particles to 600°C in Argon atmosphere Coefficient of thermal expansion

Coefficient of thermal expansion Relative elongation

Relative elongation Thermogravimetric (TG) curves recorded for the Ni powder, Ni+Al powder a Ni+Al green compact oxidized at 800 °C

Thermogravimetric (TG) curves recorded for the Ni powder, Ni+Al powder a Ni+Al green compact oxidized at 800 °C DTA record for the Ni+Al green compact heated to 750 °C in argon or air atmosphere

DTA record for the Ni+Al green compact heated to 750 °C in argon or air atmosphere