Pokročilé technológie / Techniky povlakovania /

Nickel coating of carbon fibres to increase electric conductivity in polymer matrix composites.

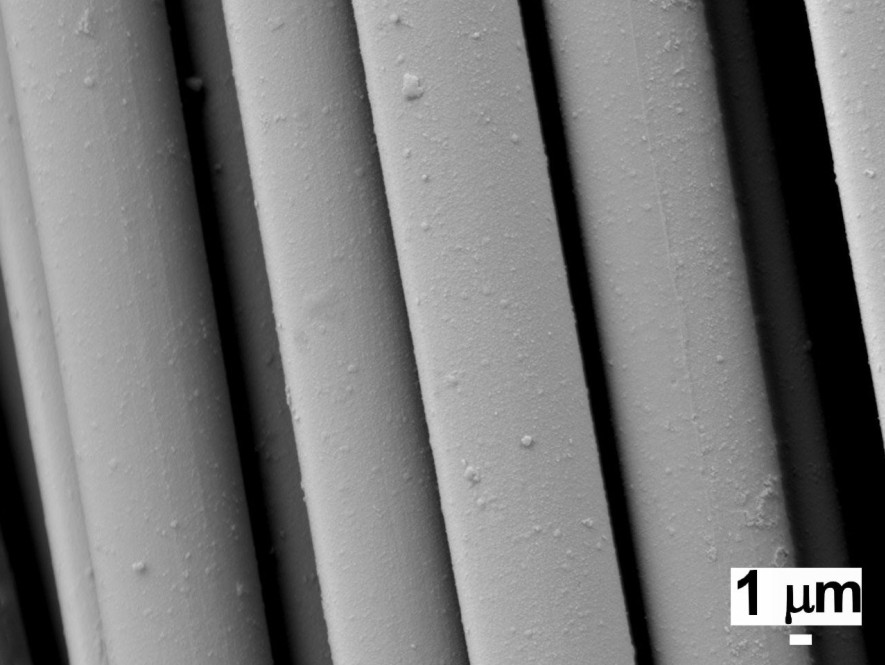

Copper coated of Torayca T-300 carbon fibres

Copper coated of Torayca T-300 carbon fibres

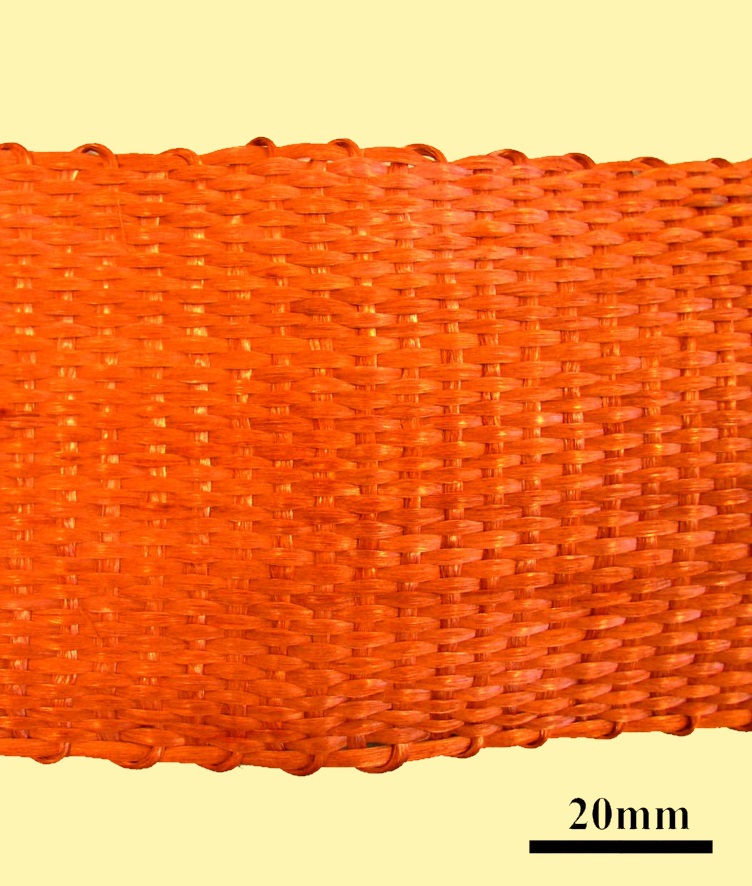

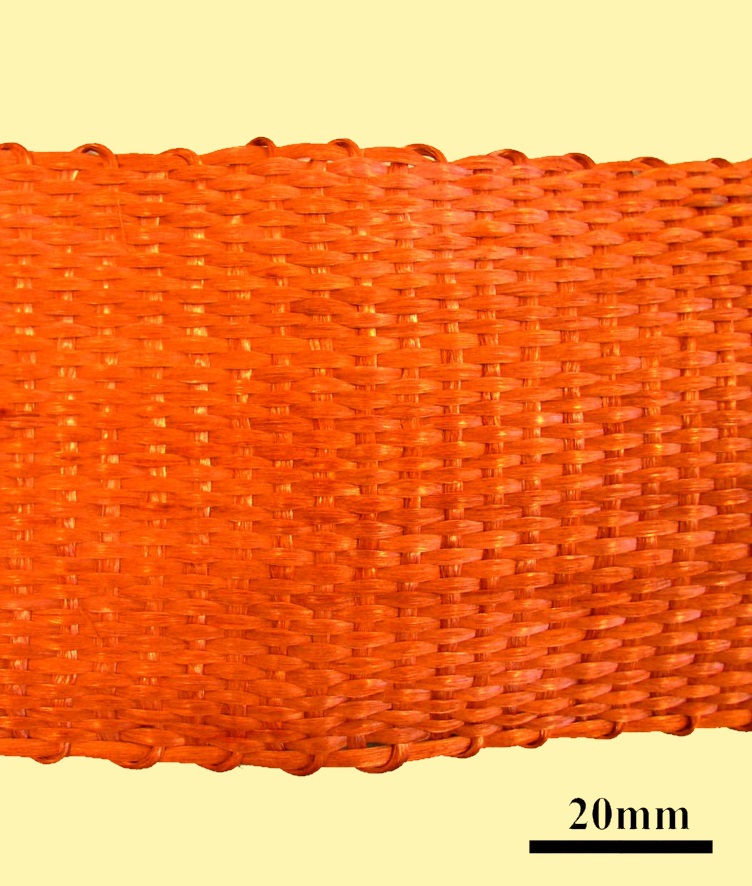

Fabric made from copper coated carbon fibre tow

Fabric made from copper coated carbon fibre tow

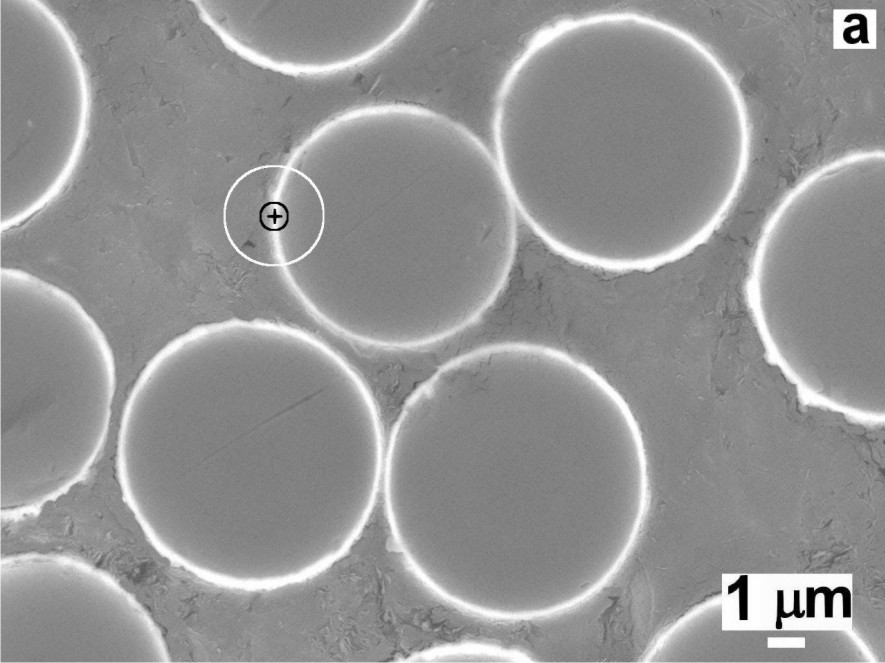

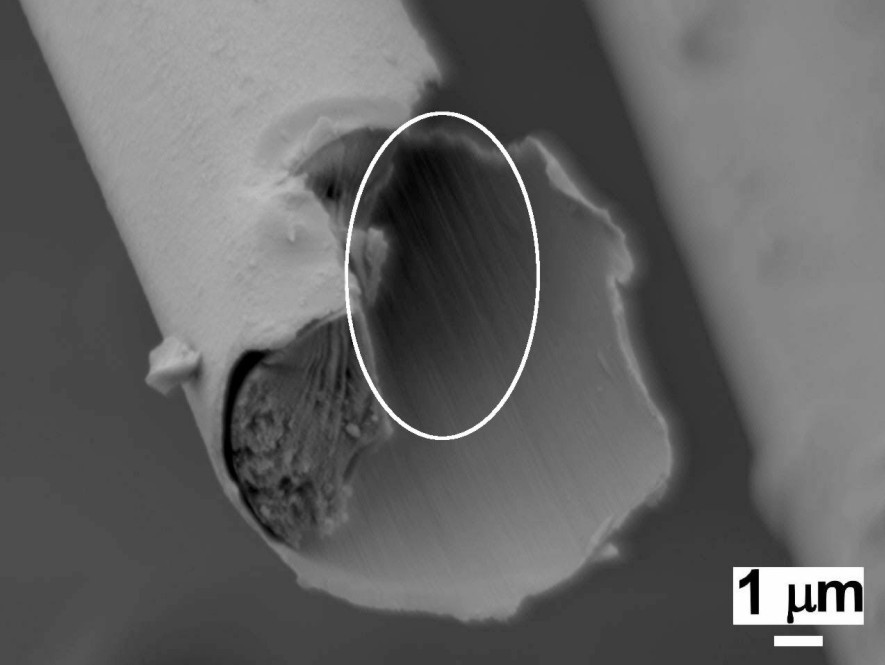

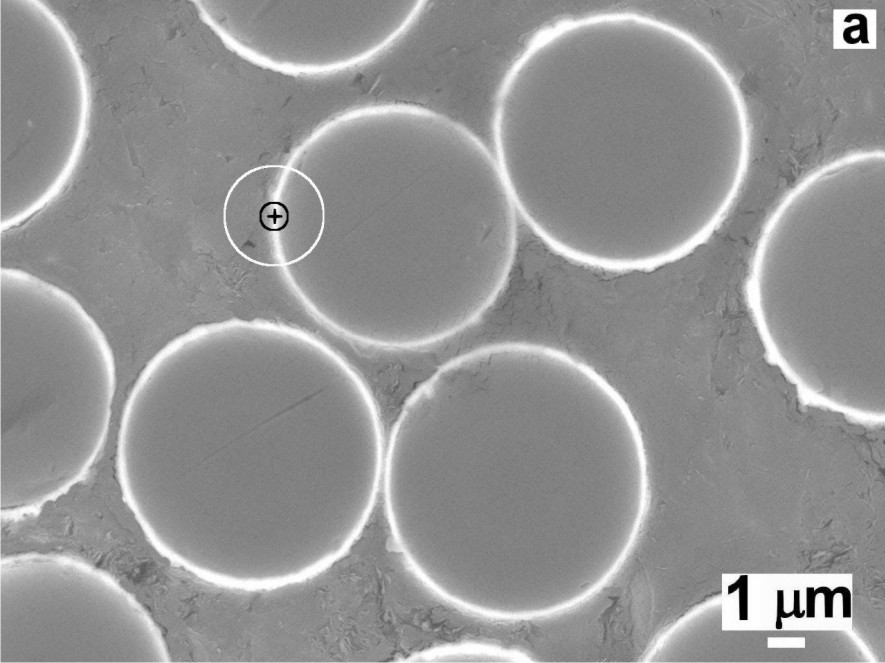

Cross sectional view of Ni coated carbon fibres

Cross sectional view of Ni coated carbon fibres

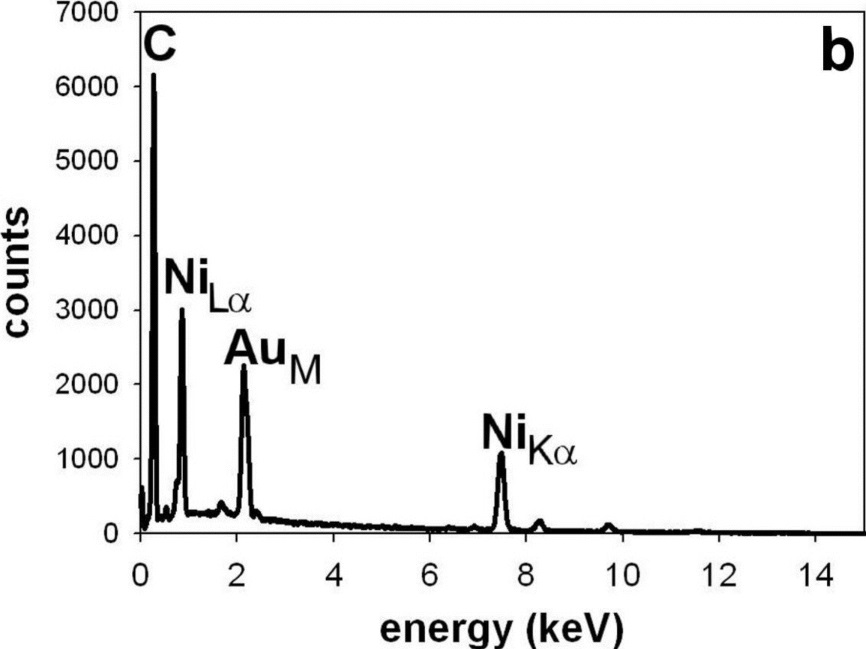

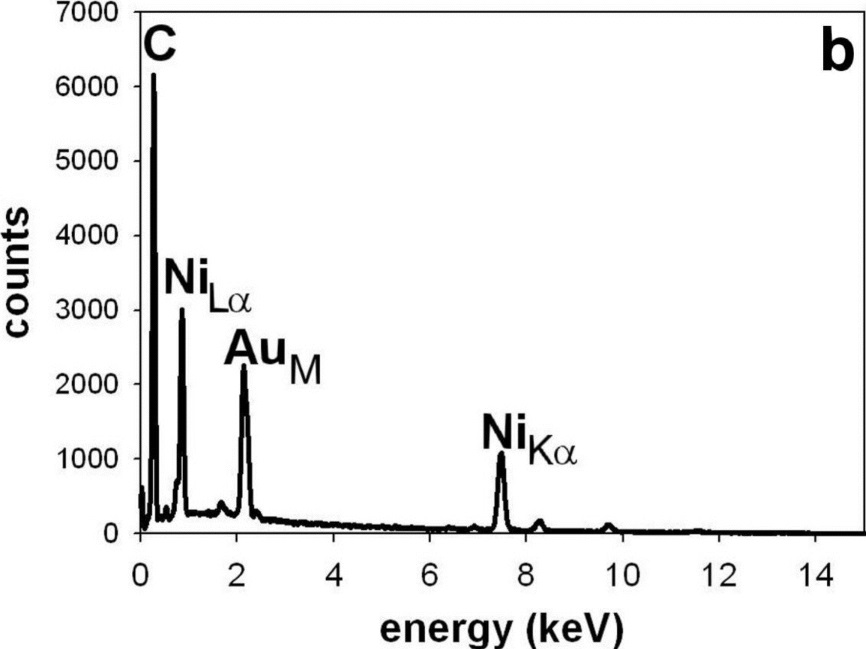

EDS spectrum acquired from Ni coating (point +)

EDS spectrum acquired from Ni coating (point +)

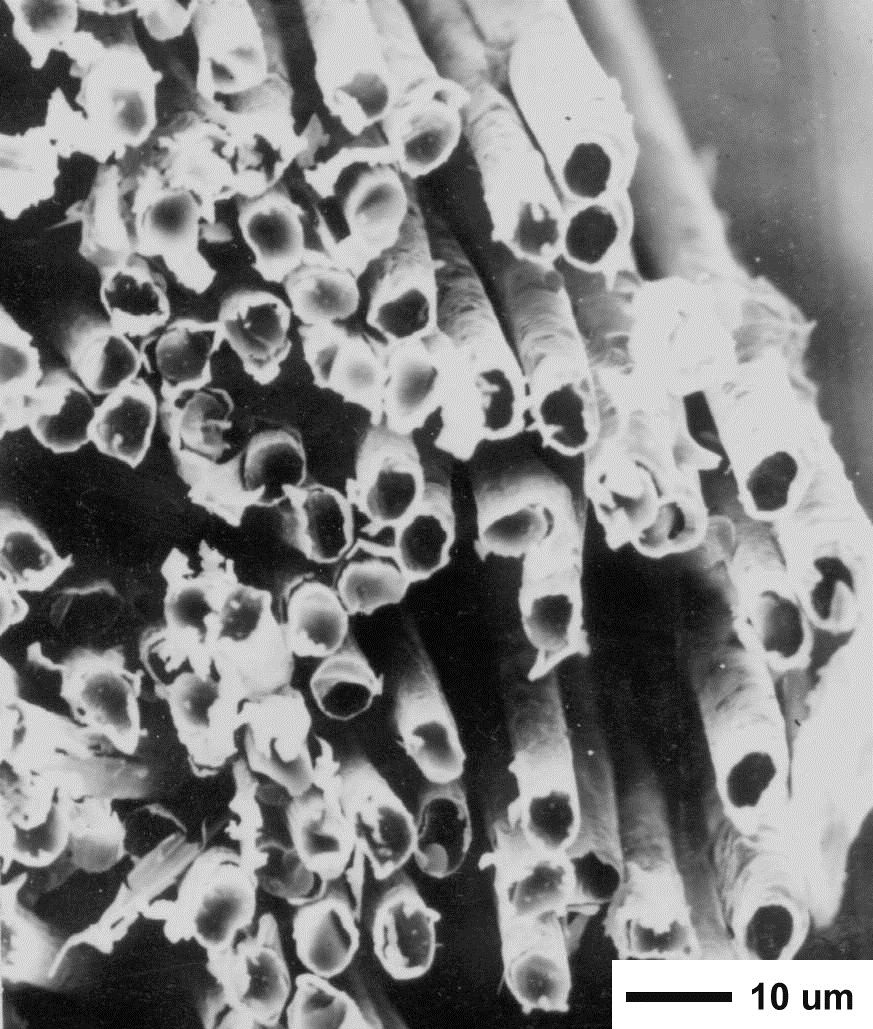

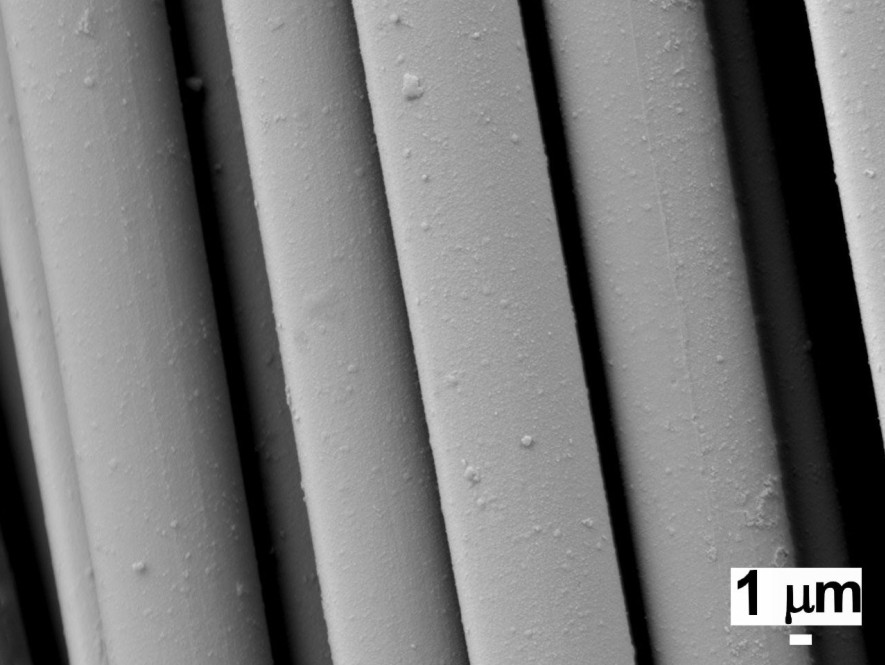

Ni coated carbon fibre tow

Ni coated carbon fibre tow

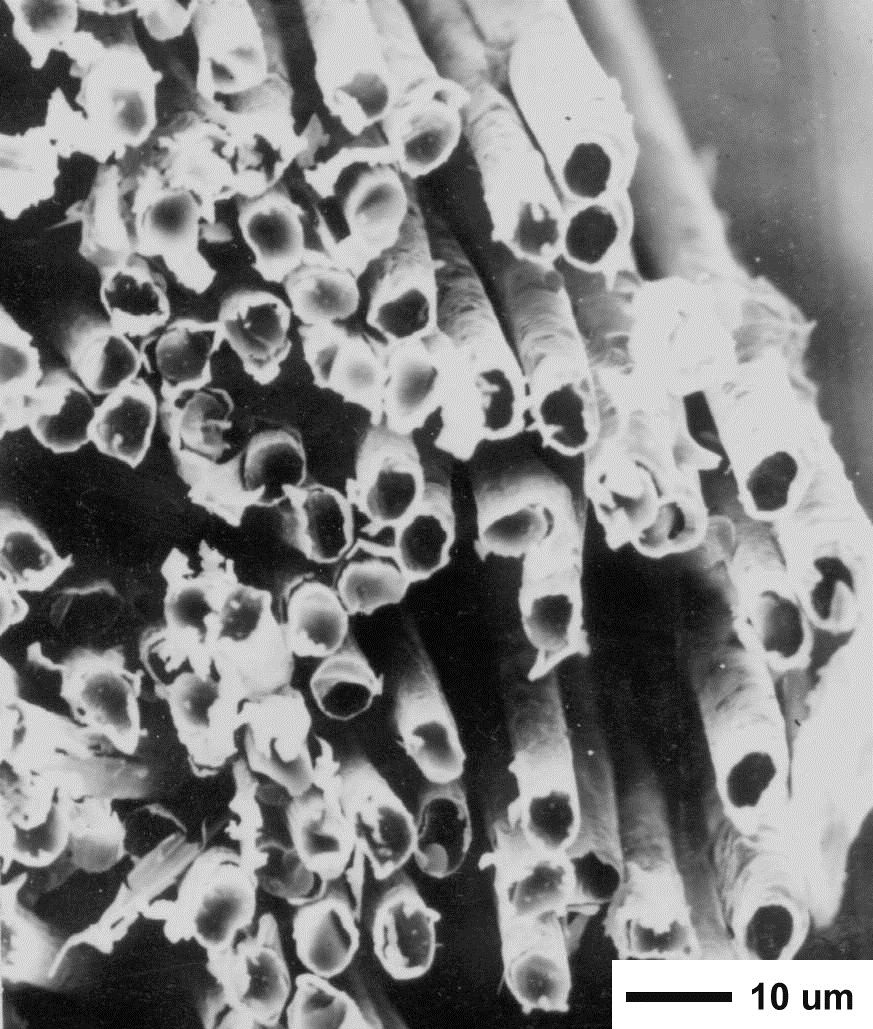

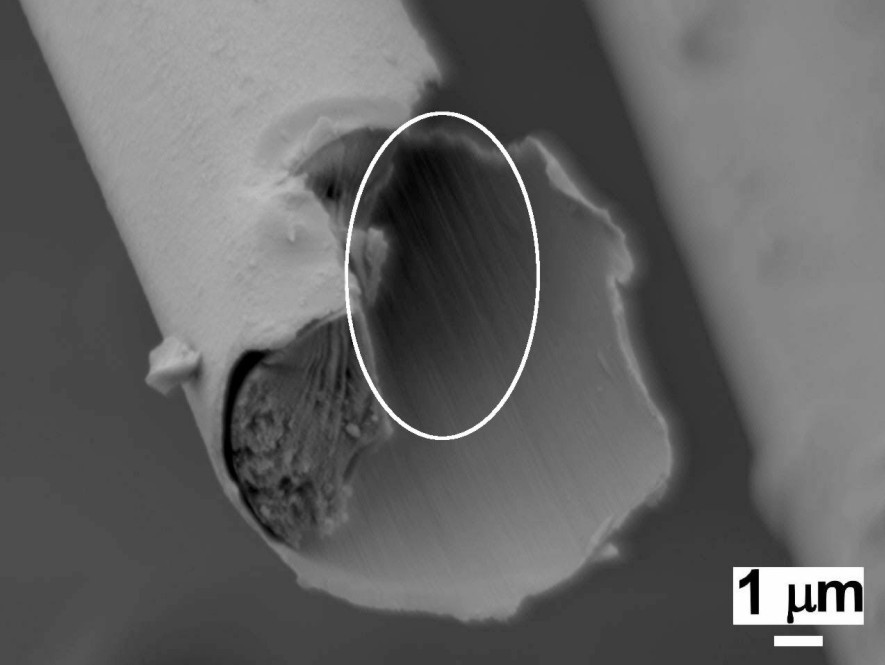

Ni coating imprinting the C fibre surface morphology

Ni coating imprinting the C fibre surface morphology

Fibre coating

General description

Diffusion bonding of coated multifilament fibre tows is used for the preparation of metal matrix composites (MMCs). Some coated layers prevent reaction between fibres and matrix or increase the surface wettability of fibres by molten metal.Principle of operation

Metal coatings on continuous multifilament carbon fibre tows can be obtained by various technologies, such as chemical vapour deposition (CVD) process, physical vapour deposition (PVD) process, autocatalytic (electroless) plating process, electrolytic (galvanic), etc. All methods related to metals deposition on strand of fibres have common problem – i.e. how to spread effectively the tow at the beginning of the deposition process.Typical applications

Preparation of copper matrix/carbon fibre composite.Nickel coating of carbon fibres to increase electric conductivity in polymer matrix composites.

Copper coated of Torayca T-300 carbon fibres

Copper coated of Torayca T-300 carbon fibres Fabric made from copper coated carbon fibre tow

Fabric made from copper coated carbon fibre tow Cross sectional view of Ni coated carbon fibres

Cross sectional view of Ni coated carbon fibres EDS spectrum acquired from Ni coating (point +)

EDS spectrum acquired from Ni coating (point +) Ni coated carbon fibre tow

Ni coated carbon fibre tow Ni coating imprinting the C fibre surface morphology

Ni coating imprinting the C fibre surface morphologyEquipment

- Lab-scale facility with several steps – desizing, electroless metal coating, galvanic metal coating, winding