Development of new metal matrix composites based on high modulus short carbon fibres with high dimensional stability at elevated temperatures

| Project start: | 01.01.2010 |

|---|

| Project end: | 31.12.2012 |

|---|

| Programme: | VEGA |

|---|

| Project number: | 2/0158/10 |

|---|

| Institute position in the project: | The only one project investigator |

|---|

| Project leader: | Pavol Štefánik |

|---|

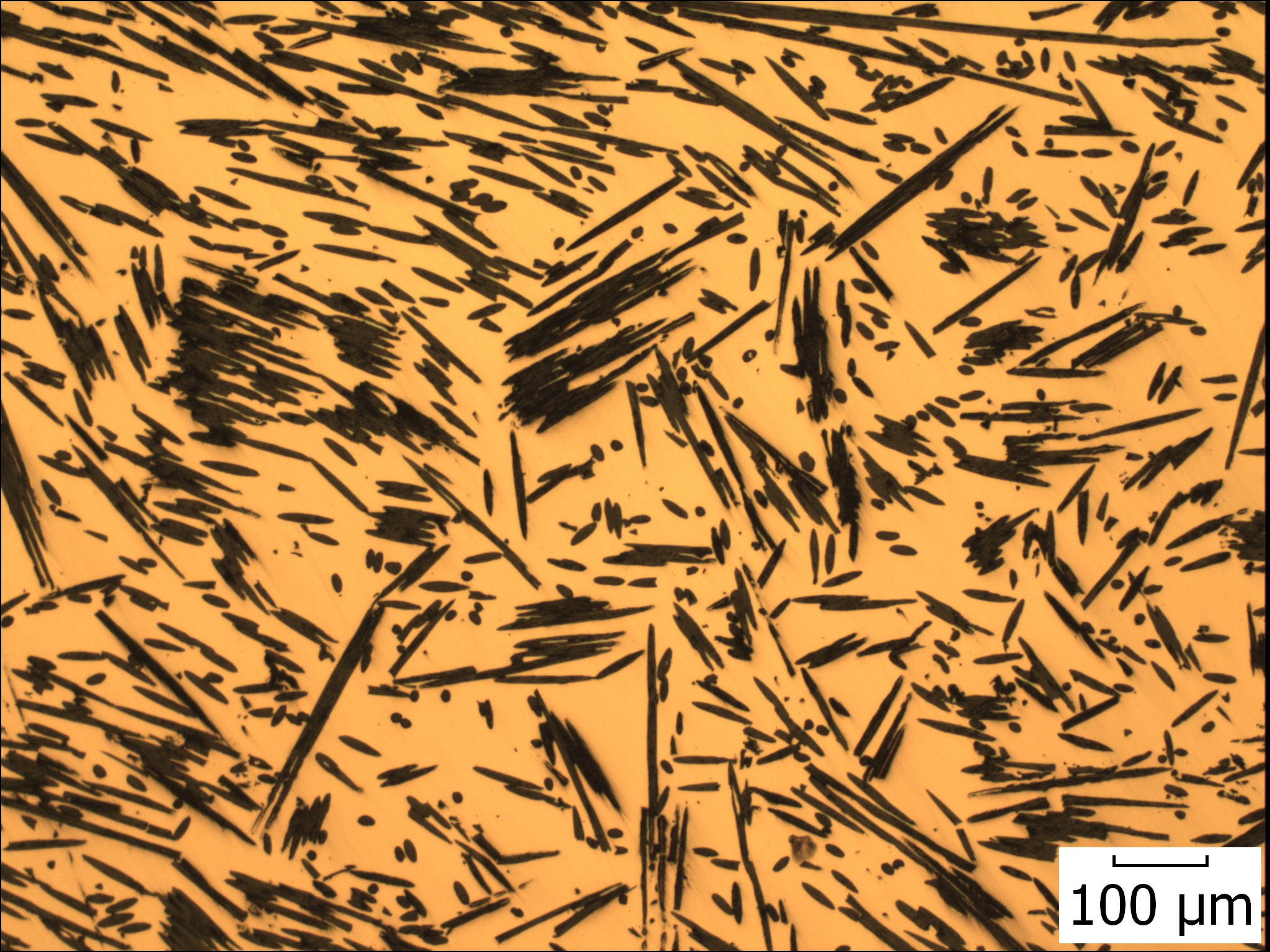

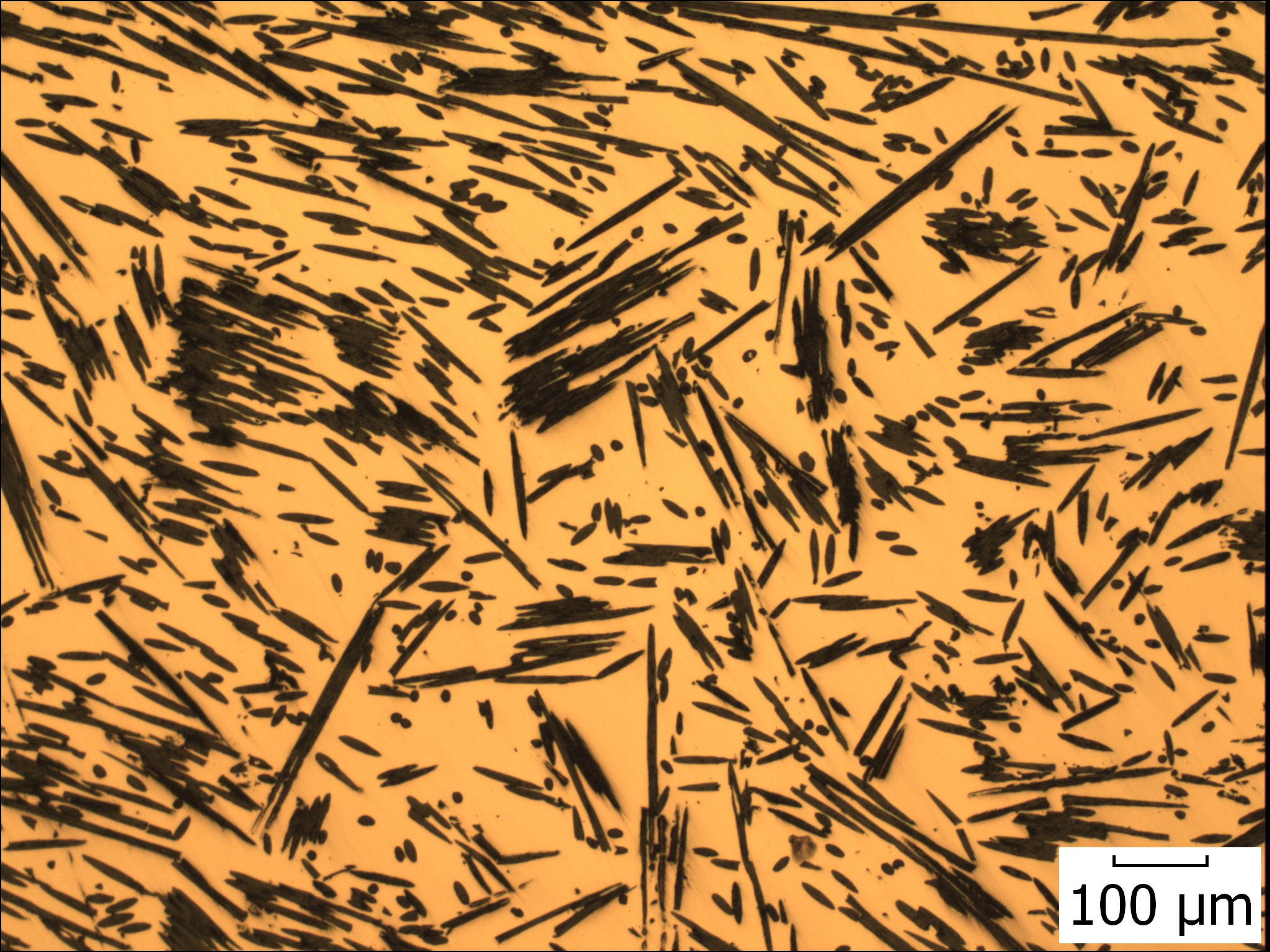

The composites with short carbon fibres and three types of metal matrices were prepared via gas pressure infiltration of molten metal into fibre preform. The fibres exhibited high mechanical properties and high thermal conductivity, but the properties of composite depend also on orientation of fibres. To increase the adhesion of metals (Mg or Cu) to carbon fibre surface the alloying elements (Al or Cr) were added into metal matrix. During infiltration of Al into carbon fibre preform the undesirable aluminium carbide is formed. To inhibit this reaction the Mg alloying element was added to Al and the parameters of infiltration were optimised. The thermal cycling in temperature range 20-350 °C of prepared composite was realised and coefficients of thermal expansion were calculated. The expansion of composites in whole temperature interval was significantly lower than in the case of pure metals. The highest thermal conductivity possesses the Cu matrix composite with 0.2 % of Cr.

Microstructure of composite prepared by infiltration of short carbon fibres (Granoc XN-100) with molten Cu0.2Cr copper alloy