Hard nanostructured coatings

Summary

Hard nanostructured coatings based on ceramic materials such as nitrides, borides, etc., are widely used in engineering systems to protect structural materials during operation in harsh environments. Transition metal nitrides (TMNs), especially Ti-Al-N and Cr-Al-N ternaries, generally characterized by cubic NaCl-structure (B1) solid solutions, or nanocolumnar and nanocompositeTiBx and Ti-B-N,are typical representatives of contemporary industrialcoatings with emphasis on high hardness, high thermal stability, good oxidation resistance, and chemical inertnesswhich allow for significant extension of tools' lifetimesultimately resulting in drastic reductions of costs caused by wear.Objectives

In order to further improve and/or tune theaforementioned TMNs properties, for example thermal stability improvement, the concept of multicomponent alloying with nitrides of elements from groups IIIB, IVB, VB and VIB (Y, Zr, Hf, V, W, Nb, Ta, and Mo) is a promising approach. Unfortunately, ceramics are typically characterized by inherently low toughness, where the latter is defined as material's ability to resist crack initiation and propagation up to fracture. This problem limits the potential use of hard but brittle materials as protective coatings. The most typical example is the sudden failure of machining tools coated with ceramics overlayers during industrial processing. In order to avoid brittle failure due to cracking, wear-resistant coatings must be both hard and tough.Achievements

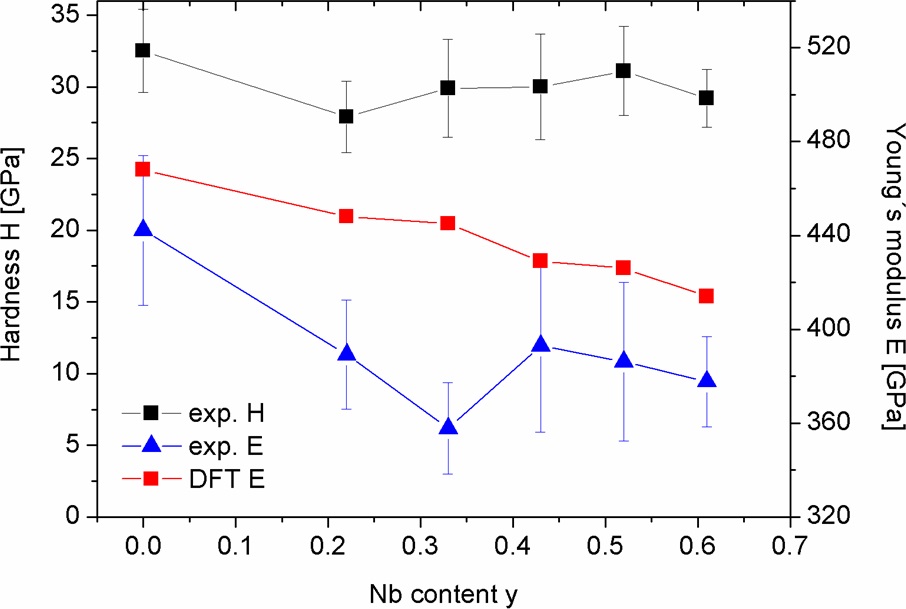

We reported improved thermal stability in hard nanostructured coatings where we have grown Cr-Al-Y-Ta-N coatingswith different Ta contents in the range of 0 to 10.4 at.%All prepared Cr-Al-Y-Ta-N coatings in the as-deposited state exhibit a single phase cubic structure identified as fcc-CrAlY(Ta)N solid solution. The structural investigation indicates that tantalum-free Cr-Al-Y-N coatings start to decompose when the annealing temperature exceeds 900 °C and results in the formation of w-AlN precipitates in the remaining Cr-rich matrix. Unstable Cr–N bonds at higher temperatures and N-loss lead to dual-phase structure consisting of w-AlN and bcc-Cr. The presence of Ta in the solid solution shifts the start of the decomposition process to higher temperatures >1000 °C for Cr-Al-Y-Ta-N with Ta content of 10.4 at. %), leading to improvement of thermal stability compared to CrAlYN. This improved thermal stability can be attributed to higher cohesive energies of the Ta containing solid solutions. Decompositionof solid solutions during gradual increase of temperature to 1200 °C accompanied by a loss of nitrogen continues with the formation of cubic and hexagonal Cr- and Ta-containing binaries or ternaries.We also reported our solution, how can we improve toughness in brittle ceramic hard coatings, where we have grown Ti1-x-yAlxNbyN coatings on WC/Co and Si(001) substrates via reactive unbalanced dc magnetron co-sputtering with Nb contents in the range 0 ≤ y ≤ 0.61 and stoichiometry N/(Ti + Al + Nb) = 1.00±0.01. All as-deposited Ti1-x-yAlxNbyN coatings exhibit single phase cubic sodium chloride (B1) structure identified as TiAl(Nb)N solid solutions. Increasing Nb contents promote the evolution of Ti1-x-yAlxNbyN film textures from preferentially 111, for low y, to essentially fully 200 for high y values accompanied by an overall increase in average defect-free length from ~ 14 nm to ~ 24 nm. The highest hardness, ~ 32.5 GPa, and the highest Young´s modulus, ~ 442 GPa, were obtained in Nb-free Ti0.46Al0.54N exhibiting pronounced 111 growth-orientation. Increasing the Nb content results in a slight reduction of hardness, found to vary in the range from ~ 27.9 to ~ 31.1 GPa accompanied by a significant reduction of Young´s moduli, which decreases by up to -20% (from ~ 442 to ~ 358 GPa), suggesting enhanced plasticity for in the highly NbN-alloyed coatings. DFT calculated density of states, corroborated by UPS analyses, show that the addition of Nb modifies nearest-neighbor metal-N bonds from being prevalently ionic to more covalent and provides a significant contribution to the metallic character for valence states located at the Fermi level while also strengthening second-neighbor bonds at higher binding energies. This explains dramatically reduced shear resistance and elastic stiffness in TiAlNbN vs. TiAlN at the cost of slight losses in strength/hardness. Summarizing, progressive increase in Nb contents, corresponding to a monotonic increase in the valence electron concentration of deposited TiAlNbN coatings, retains high hardness while reducing stiffness and improving ductility, indicating enhanced toughness.

Indentation hardness H and Young's modulus E of as-deposited Ti1-x-yAlxNbyN coatings as a function of Nb content y. DFT E values (Hill average) are plotted for comparison.

Indentation hardness H and Young's modulus E of as-deposited Ti1-x-yAlxNbyN coatings as a function of Nb content y. DFT E values (Hill average) are plotted for comparison.Additional reading

M. Mikula, D. Plašienka, Davide G. Sangiovanni, M. Sahul, T. Roch, M. Truchlý, M. Gregor, Ľ. Čaplovič, A. Plecenik, P. Kúš, Toughness enhancement in highly NbN-alloyed Ti-Al-N hard coatings, Acta Materialia 121 (2016) 59-67.M. Mikula, D. Plašienka, T. Roch, K. Štyráková, L. Satrapinskyy, M. Drienovský, V. Girman, B. Grančič, A. Plecenik, P. Kúš,Structural evolution of TaN-alloyed Cr-Al-Y-N coatings, Surf. Coat. Technol. 259 (2016) 698-706.

M. Mikula, T. Roch, D. Plašienka, L. Satrapinskyy, P. Švec sr., D. Vlčková, M. Dvoranová, B. Grančič, M. Gregor, A. Plecenik, P. Kúš, Thermal stability and structural evolution of quaternary Ti-Ta-B-N coatings, Surf. Coat. Technol. 259 (2014) 698-706.

Related projects

- Multicomponent nanocomposite coatings prepared by highly ionized deposition technologies, 2015 - 2018