Oxidation of Al powders

Summary

The oxidation behaviour of gas-atomized A1050, A5083, A6061 and A7075 powder on heating to temperature needed for successful compaction (hot forging/extrusion) in air or in nitrogen atmosphere was studied. The main attention was paid to microstructural changes caused by potential reaction of alloying elements with high affinity to oxygen/nitrogen (e.g. Mg) and their effect to mechanical properties of final extruded profiles.Objectives

Complex powder surface phenomena, which can yield irreversible microstructural changes of Al powder and deteriorate the properties of the final part, take place on heating. The main objectives of this systematic study were to- investigate the effect of the surrounding atmosphere on the microstructural changes in the powder particle and at its surface;

- determine the effect of these changes on the mechanical properties and also on the subsequent thermal treatment of final extruded profiles;

- determine the optimum technological parameters for heating of Al powder compacts prior to the hot extrusion.

Achievements

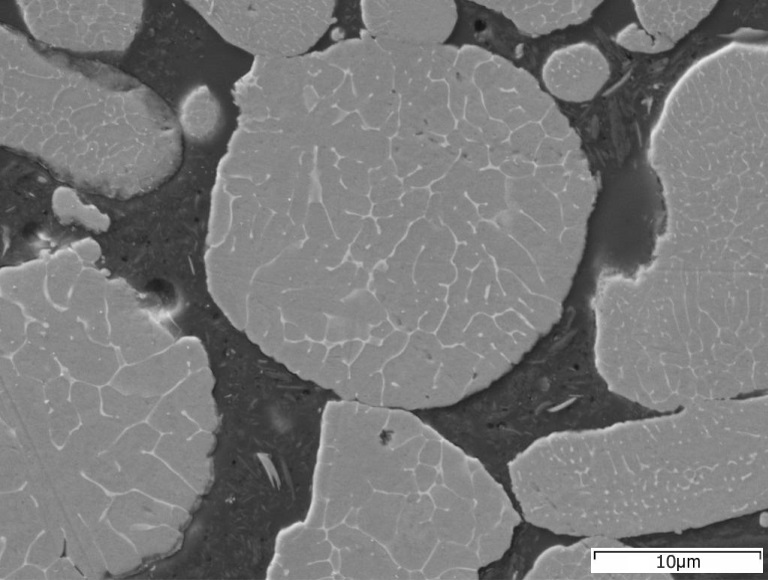

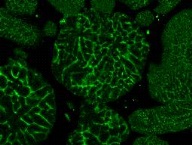

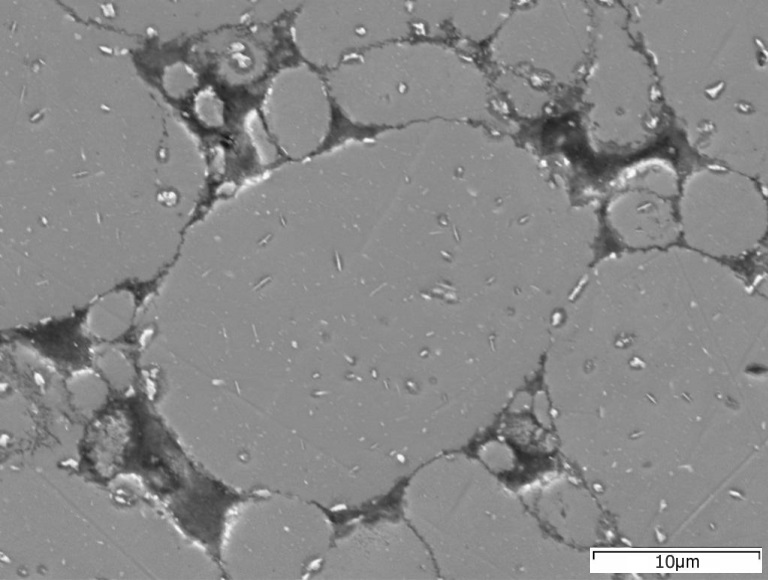

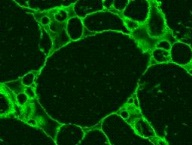

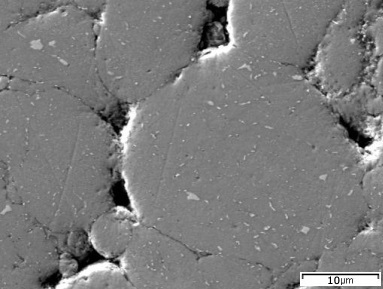

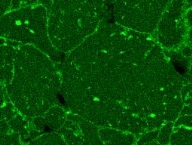

The onset and intensity of oxidation were affected by the Mg content, the surface area of the powder and the entire volume of the powder green compacts. Mg diffuses from the powder core toward the native Al2O3 surface layer where it reacts with oxygen present in this layer forming MgO phase. This results in the depletion of metallic Mg in the alloy and leads thus to inefficient Al-Mg solid solution strengthening or precipitation hardening. The heating in air supports the Mg redistribution and oxidation significantly. Moreover exothermic heat developed during oxidation of Al and Al alloy powders in air resulted in intense overheating thus supporting intense surface reactions and microstructural changes. All these effects have strong negative impact on the final strength of extruded profiles. Heating Al alloy powder green compacts under nitrogen significantly limits the depletion of Mg from the powder core, avoids overheating the powder green compacts, and the extruded powder materials exhibit expected strength values.Microstructures and Mg maps of loose A7075 powder showing the enrichment of the powder surface with Mg

Microstructure and Mg map after manufacturing Microstructure SEM

Microstructure SEM EDX Mg Ka1_2

EDX Mg Ka1_2 Microstructure SEM

Microstructure SEM EDX Mg Ka1_2

EDX Mg Ka1_2 Microstructure SEM

Microstructure SEM EDX Mg Ka1_2

EDX Mg Ka1_2Additional reading

KRÍŽIK, Peter - BALOG, Martin - ILLEKOVÁ, Emília - ŠVEC SR., Peter - MATKO, Igor - ŠTĚPÁNEK, Matej - NOSKO, Martin - SIMANČÍK, František. The oxidation behavior of gas-atomized Al and Al alloy powder green compacts during heating before hot extrusion and the seggested heating process. In Journal of Materials Processing Technology, 2014, vol.214, p.1165-1172. ISSN 0924-0136.KRÍŽIK, Peter - BALOG, Martin - ILLEKOVÁ, Emília - ŠVEC, Peter - SIMANČÍK, František. Oxidation of Al and Al-based Gas Atomized Powders. In Euro PM 2011: congress and exhibition. CD Proceedings. Barcelona, 9.-14.10.2011. - Shrewsbury: EPMA, 2011, p.301-308.

Related projects

- Application of advanced metallic materials for stiffness enhancement of lightweight structural components, 2011 - 2014