Advanced materials / Lightweight materials /

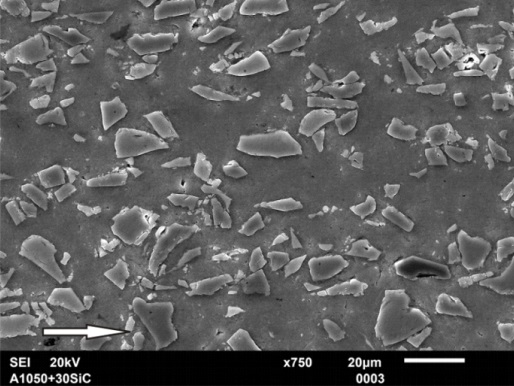

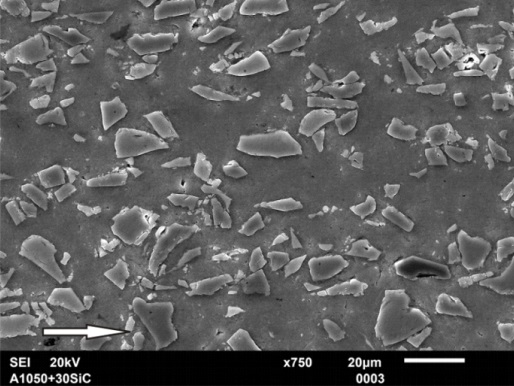

SEM micrograph of A1050 + 30 vol.% SiCp composite

SEM micrograph of A1050 + 30 vol.% SiCp composite

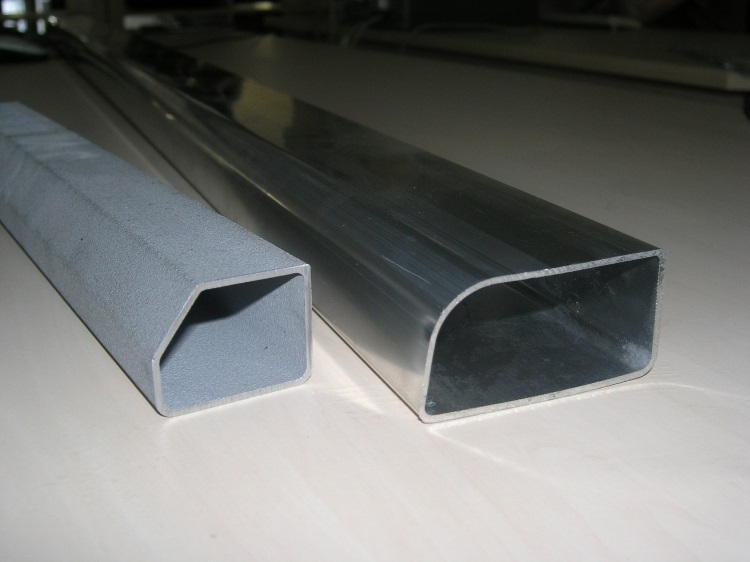

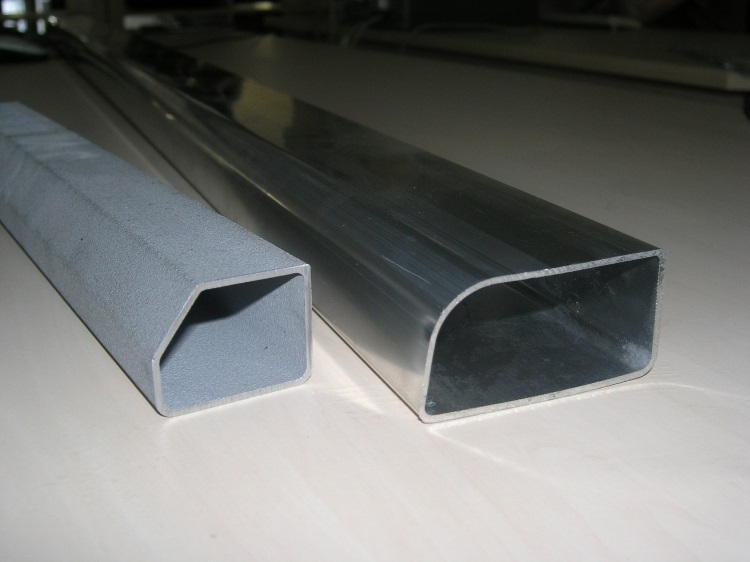

Extruded composite profiles for automotive industry

Extruded composite profiles for automotive industry

Various routes can be used to prepare such composite including solid state as well as liquid state technologies.

Aluminium matrix composites reinforced with boron fibres combine low density Al matrix with high strength and high elastic modulus B fibres. They are prepared by vacuum diffusion bonding technique.

Depending on the parameters of diffusion bonding composites with different interfacial strengths can be prepared. In optimal conditions composites exhibit cumulative failure modes i.e. the crack that appears in boron fibre proceeds to the next fibre where it is stopped and turned off its course along the interface. The composite breaks only after accumulation of critical failure events (fibre breakage).

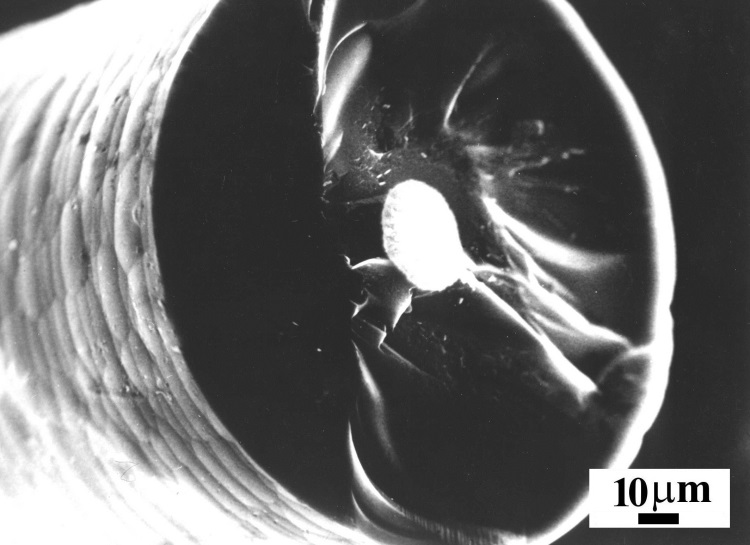

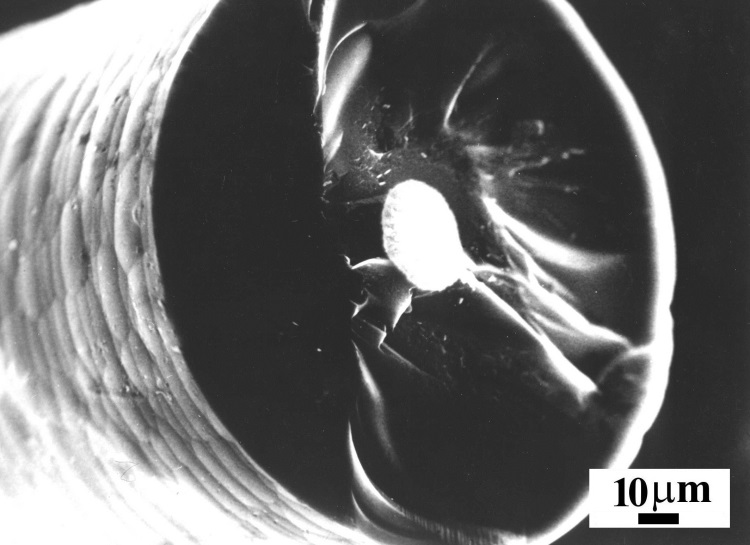

Structure of B fibre

Structure of B fibre

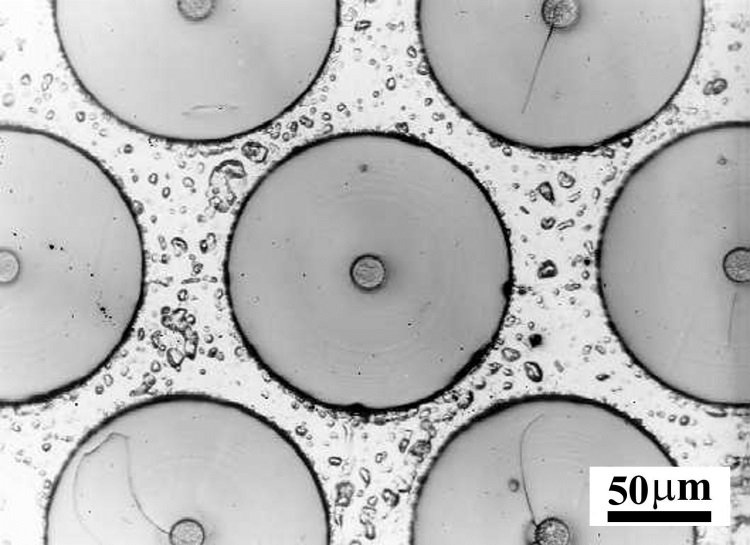

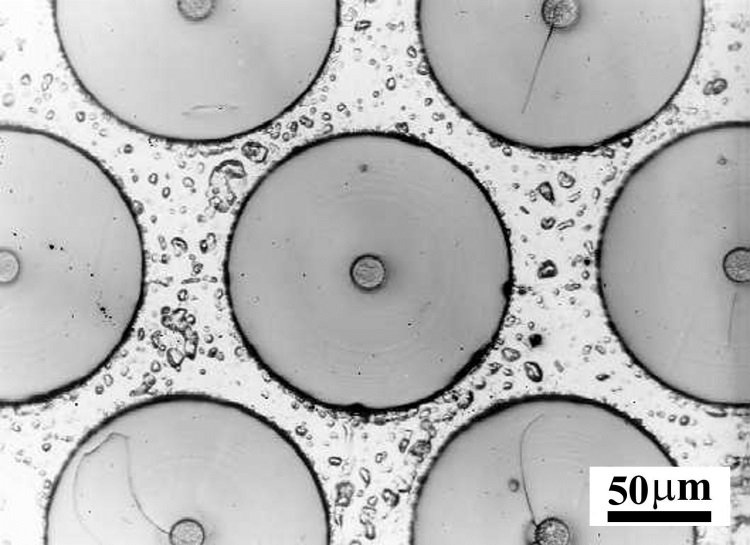

Structure of Al-B composite

Structure of Al-B composite

Aluminium matrix composites

Extruded Al/SiC composites

General description:

Al profiles reinforced with small SiC particles are hot extruded from powder mixtures using standard aluminium alloy powders. The obtained geometry and complexity is similar to typical aluminium alloy profiles, nevertheless, due to the effect of ceramic particles, the profiles possess significantly higher specific stiffness and wear resistance. As a matrix, the standard wrought Al alloy powders (A2024, A3003, A5083, A6061, A7075) can be used. The volume content of small SiC particles can vary from 0 up to 40 % (typically 10 - 30 %).Typical properties

Al 5083 alloy composite reinforced with 20 vol.% of SiC particles:- young’s modulus (E): ~100 GPa

- density: ~2,6 g/cm3

- ultimate tensile strength UTS: ~400 MPa

- yield stress YS: ~330 MPa

- elongation to fracture A: ~4 %

- coefficient of thermal expansion CTE: ~ 17 ppm/K

Main benefits

Due to high Young’s modulus and low density of composites, the obtained profiles exhibit 50% higher specific stiffness if compared with conventional Al-alloy profiles. Beside this, the composites possess low CTE, high wear resistance and excellent structural stability at elevated temperatures. They are industrially produced using conventional hot extrusion, thus keeping the costs at a moderate level (<10 EUR/kg).Potential applications

Al/SiC composite profiles are successfully applied in lightweight construction, especially in stiffness limited design (car body frames, moving arms of robots, stiff lightweight structural struts, machine frames for precise cutting, welding machines, sports equipment, aerospace industry,..) wear resistant sliding profiles, or parts where lower CTE and high temperature stability is required. SEM micrograph of A1050 + 30 vol.% SiCp composite

SEM micrograph of A1050 + 30 vol.% SiCp composite Extruded composite profiles for automotive industry

Extruded composite profiles for automotive industryAdditional reading

KRÍŽIK, Peter - BALOG, Martin - MAŤKO, Igor - ŠVEC, Peter - ČAVOJSKÝ, Miroslav - SIMANČÍK, František. The effect of a particle-matrix interface on the Young´s modulus of Al-SiC composites. In Journal of Composite Materials, 2016, vol. 50, no. 1, p. 99-108. (1.242 - IF2015). ISSN 0021-9983.Aluminium matrix composite reinforced with boron fibres

General description

Many mechanical properties of structural materials e.g. strength, hardness, can be improved by proper alloying or thermal treatment. However, there are only very limited possibilities how to improve the modulus of elasticity. The most efficient way is to combine metallic matrix with some ceramic reinforcement (particles, fibres) exhibiting substantially higher modulus of elasticity.Various routes can be used to prepare such composite including solid state as well as liquid state technologies.

Aluminium matrix composites reinforced with boron fibres combine low density Al matrix with high strength and high elastic modulus B fibres. They are prepared by vacuum diffusion bonding technique.

Main benefits

Al-B composites provide unique structural material with extraordinary specific strength and stiffness. The composite can be prepared in the various kinds of profiles including tubes.Main properties

The experimental tests confirmed the tensile strength of Al/B composite reinforced with 60 vol. % of unidiretionally aligned boron fibres as high as 1400 MPa and the elastic modulus 266 GPa with the overall density of 2 565 kg.m-3. This means that the elastic modulus is higher than that of steel while the density is lower than that of aluminium.Depending on the parameters of diffusion bonding composites with different interfacial strengths can be prepared. In optimal conditions composites exhibit cumulative failure modes i.e. the crack that appears in boron fibre proceeds to the next fibre where it is stopped and turned off its course along the interface. The composite breaks only after accumulation of critical failure events (fibre breakage).

Structure of B fibre

Structure of B fibre Structure of Al-B composite

Structure of Al-B compositeMain applications

Unique combination of properties predetermine the application of Al/B composites in most heavily loaded dynamic constructions. Typical examples include:- compressor turbine blades

- frames of space vehicles (space shuttle)